Pine planks were laid first so that we have a beautiful ceiling of interesting knots and grains. They give a warm and cozy feeling even in the main rooms where the ceiling height reaches about 26 feet. Over the planks they nailed 2 x 12’s and between these channels they insulated with an expanding foam that hardened to give an extremely high R-value. An air space of a couple of inches remained – just enough to hear the pitter-patter of flying squirrel feet as the little buggers took up residence the first winter. We later put up screens at suspected entry points.

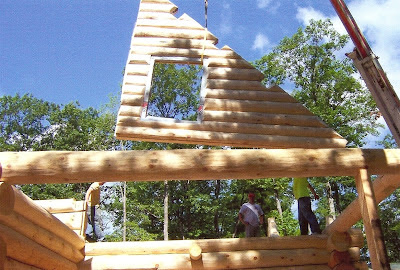

The thick insulation has been worth its price, keeping the house warm in the winter and cool in the summer. People ask us what kind of insulation we use in the walls. That’s funny because the logs are the walls. The thickness of the walls averages about a foot and a half. Where they join the thickness is only about eight inches, but the log guys put natural insulating wool between each course and before the walls were caulked my husband and I stuffed pink insulation in anywhere we could see daylight. A pine log has an R-value of 1.25 per inch so from narrowest to thickest our walls rate between R-10 to nearly R-30. We used a laser sensor to check for cold spots on a below zero winter day and our biggest heat loss is from the windows, not the logs.

The first winter we lived here the walls were not caulked (some log homes use chinking because the logs don’t fit as tightly as our scribed logs do). We had a few drafts, mice, bats, and even snow. But we had to wait a year for the logs to settle enough before caulking inside and out.